Orbital Welding

Precision Orbital Welding Services for High-Spec Applications

At Burnhouse Engineering, we provide expert orbital welding services for clients who demand precision, repeatability, and reliability. Using advanced orbital welding equipment, our team delivers high-integrity welds ideal for critical applications in the pharmaceutical, food and beverage, aerospace, and semiconductor industries.

What Is Orbital Welding?

Orbital welding is an automated welding process where the welding arc rotates 360 degrees around a stationary pipe or tube. It ensures highly consistent, clean welds with minimal operator intervention — ideal for high-purity and high-pressure systems.

Our experienced team uses state-of-the-art orbital TIG welding systems to create flawless welds that meet the strictest industry standards, from sanitary piping systems to gas lines and heat exchangers.

Benefits of Orbital Welding

Choosing orbital welding from Burnhouse Engineering means:

- Superior Weld Quality – repeatable, smooth, and contamination-free welds

- Increased Productivity – faster cycle times and reduced rework

- High Purity – ideal for cleanroom and sterile environments

- Excellent Traceability – every weld logged and documented

- Cost Efficiency – minimal waste, reduced risk of failure

Whether you’re installing a new process system or upgrading existing pipework, orbital welding provides a professional finish with consistent weld integrity.

What Is Orbital TIG Welding?

Orbital TIG welding (Tungsten Inert Gas) is a fusion welding process using a non-consumable tungsten electrode and shielding gas (usually argon) to protect the weld zone. It’s the gold standard for welding stainless steel tubes in high-purity applications.

Our orbital TIG welders are programmed to match your material specification, tube diameter, and wall thickness, ensuring consistent weld geometry and performance across every joint.

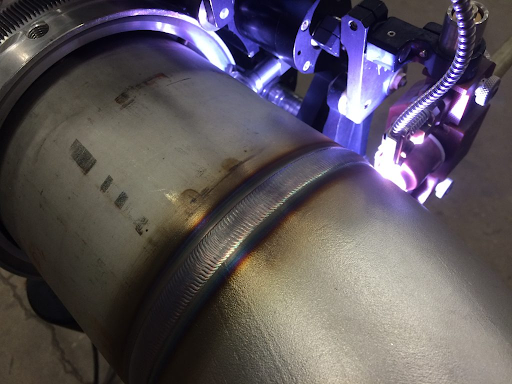

What Is an Orbital Welding Machine?

An orbital welding machine consists of a programmable power supply, a weld head that rotates around the tube, and a clamping system. These machines allow for automated control of speed, arc current, shielding gas, and dwell time — delivering precise and repeatable welds without manual variability.

At Burnhouse Engineering, we invest in top-tier orbital welding equipment from leading manufacturers, ensuring consistent quality from first weld to last.

Applications of Orbital Welding

Orbital welding is used across industries where cleanliness, strength, and consistency are non-negotiable:

- Pharmaceutical and Biotech Piping

- Food and Beverage Process Systems

- Aerospace Hydraulic Lines

- Semiconductor Manufacturing

- Nuclear and Power Generation

If your system demands the highest quality welds with full documentation and traceability, orbital welding is the solution.

Why Choose Burnhouse Engineering?

With years of experience in high-spec metal fabrication and welding, Burnhouse Engineering brings the precision and technical know-how needed for your orbital welding projects.

- In-house and on-site orbital welding capabilities

- Coded welders trained in orbital and TIG processes

- Rigorous QA/QC procedures

- Cleanroom-ready equipment and practices

- Project management support from design to installation