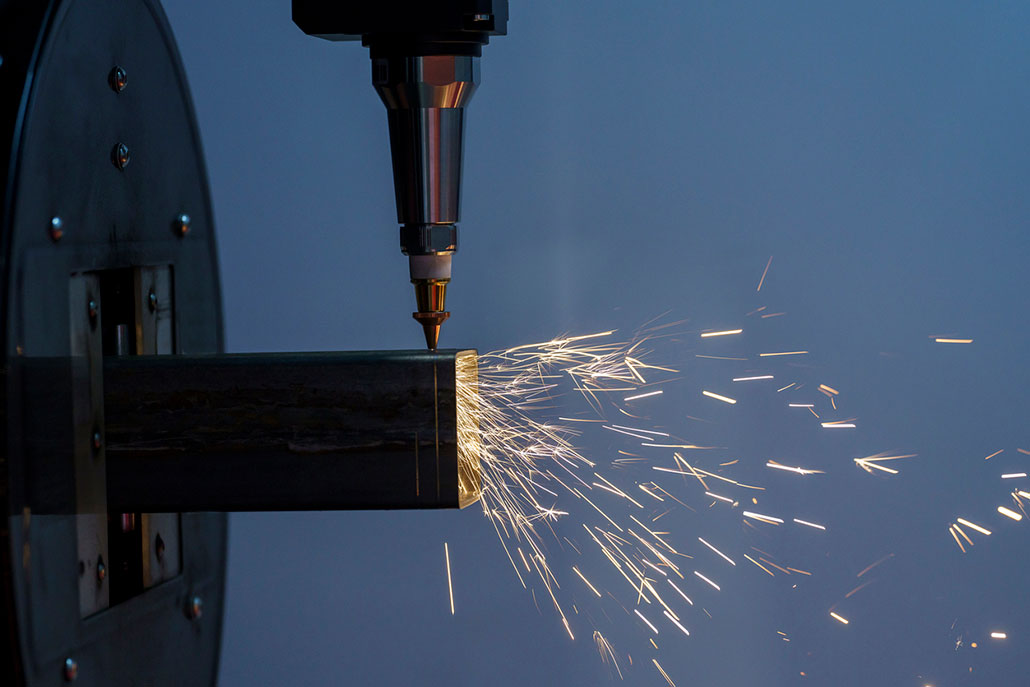

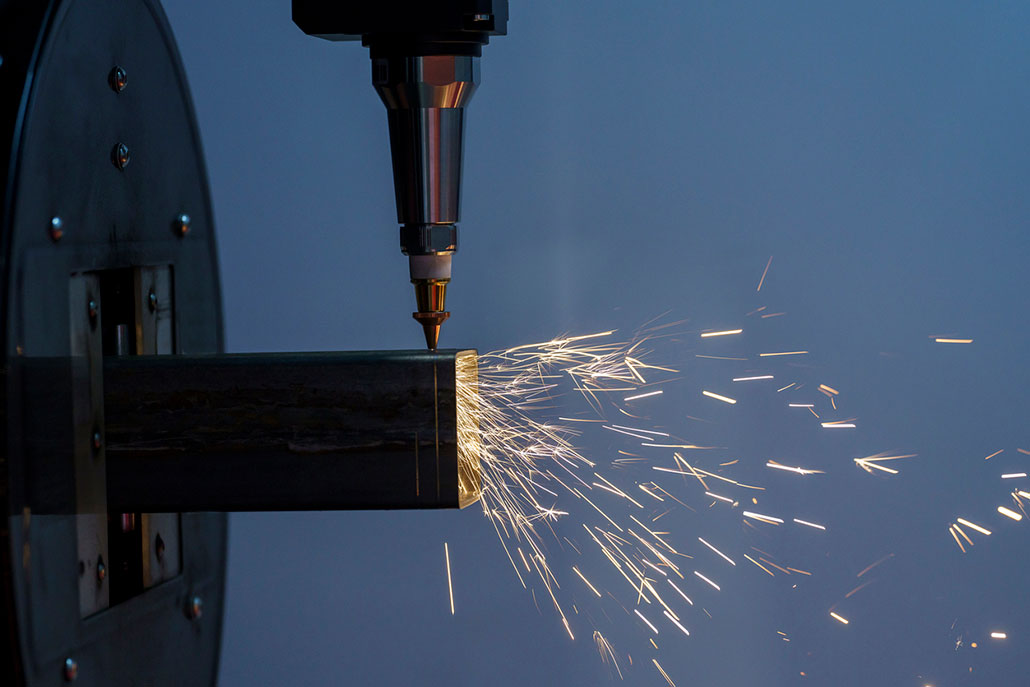

Tube Laser Cutting

Tube Laser Cutting Services

Experience precision, speed, and consistency with our tube laser cutting services for customers across Scotland and the UK. Our modern tube laser cutting machine profiles round, square, and rectangular tubes—as well as open sections—in a single, repeatable process. This streamlined approach reduces both fabrication time and costs.

CNC Laser Tube Cutter What is it and how it works

Our CNC laser tube cutter uses a rotary axis to grip and rotate material while the fibre laser profiles features with exceptional accuracy.

In a single operation, our tube laser cutting machine can produce mitres, fish-mouths, copes, slots, cut-outs, and bevels for weld preparation—plus part marking. This 3D tube profiling eliminates the need for traditional sawing, drilling, and manual jigs. The result is cleaner edges, a minimal heat-affected zone, and parts that self-locate for faster assembly.

What is it used for in Enginnering

A CNC tube laser replaces multiple set-ups, improves fit-up and shortens build time. It’s ideal for prototypes through to production when you need:

Tight tolerances and repeatability across batches

Faster assembly with tab-and-slot or bevelled joints

Consistent features for downstream bending, welding or machining

Materials & Thicknesses the CNC Pipe Laser Cutting Machine Handles

We routinely engineer:

- Mild/Carbon Steel – widely used for frames, brackets and structural fabrications

- Stainless Steel (304/316) – clean finish for food, pharma and architectural work

- Aluminium – lightweight components with excellent edge quality

- Brass & Copper – feasible on modern fibre lasers; discuss reflectivity and finish needs

Profiles include round, square and rectangular tube (RHS/SHS), plus angle, channel, oval and open sections. We handle thin-wall through to heavy-wall stock; actual limits depend on diameter, grade and geometry. Share your spec and we’ll confirm the optimum cutting envelope for your part.

Materials Notes and Finishes

Typical Projects & Industries

Our tube laser cutting services support:

- Structural frames & machine bases for manufacturing and automation

- Handrails, balustrades & architectural metalwork

- Retail shopfitting & furniture for premium visual finishes

- Jigs, fixtures & guards for production environments

- Automotive & motorsport (e.g., roll-cage components)

- Agricultural, HVAC and oil & gas skid fabrications

Why Use Burnhouse Engineering

Precision & repeatability – CNC control and intelligent nesting minimise waste and variation.

One-hit processing – mitres, slots, cut-outs and bevels from a single tube laser cutting machine.

CAD-to-quote workflow – send STEP/DXF; we’ll advise on features and manufacturability.

Integrated fabrication – welding, bending, machining and finishing available for a turnkey route.

UK delivery & service – responsive lead times across Scotland and the wider UK, with QA and traceability.

We care about your project!

Our Ultra Fibre Tube Laser works to the following tolerances and specifications:

- 12kw Fibre Tube Laser

- Up to 8” x 8” in Channel, Angle, Square Tube, Rectangular Tube, Plus Round Tube and Pipe

- Mild Steel up to 20mm Thick

- Stainless Steel up to 15mm Thick

- Aluminium up to 10mm Thick

- Tolerance to +/- 0.5mm on all materials

- Runs on Nitrogen for Aluminium and Stainless

- Oxygen for Mild Steels

Supplements our other fabrication and welding processes

Get a Fast Accurate Quote

Send your STEP/DXF files with material, wall thickness, profile, quantities and any finishing notes. We’ll confirm the cutting envelope, pricing and lead time quickly—keeping your project moving.

Ready to start? Request a quote for Tube Laser Cutting Services today.